So, you’re heading to the snow! You’ve finally paid off your trip, accommodation is booked and the mountains are calling your name. Itching to go, everything is almost ready. Whether it is weeks, months or days before you leave, you rack your brain thinking of the things you are going to need for your epic adventure in the snow. Ski jackets, thermals, ski pants and snow gloves; the list goes on and is seemingly endless. There are so many things to remember and it can become incredibly overwhelming. You thought this would be an easy, fun trip but the novelty soon wears off after you realise all the things you’ve forgotten about. Lucky Snow Central is there to have your back.

Ever wondered what you should be looking for when purchasing technical outerwear for your ski holiday? Have a read of the most common terms that you will come across when purchasing your waterproof jacket and pants. If you want a one-stop-shop for everything you need to know about preparing for your snow trip or ski season, see below for a comprehensive overview by our Snow Central Experts.

Waterproofing and Breathability Measures

Waterproof and breathable fabric technology is ever changing and evolving. In the last 10 years or so, we have seen an outstanding number of new fabric technologies come onto market. Each and every different brand has their way of doing things. They will also have their own positives and negatives. Many outerwear manufacturers have teamed up with big names to bring the best products to our customers. The fabrics used have the major purpose of keeping us dry and comfortable in a wide range of weather conditions; such as light rain and snow to monsoonal rain and blizzards.

These are two terms that will come up a lot when researching outerwear and they refer to any fabric with a 'PTFE' or Polytetrafluroethlene coating or laminate membrane that inside the garment. PTFE treatment repels water, or moisture, and other external elements and allows for the transfer of moisture and vapor created by body heat or sweating from the inside of the fabric to the outside. The most well known PTFE treatment in mountain-wear garments is Gore-Tex® in a generic sense (like a Gucci handbag) when referring to waterproof and breathable ski wear. This generalisation is not entirely fair though as many other companies are doing the same thing just in a different way with different brands. There are heaps of fabric coating or laminate brands and processes available to the companies and they all perform similarly depending on the desired waterproofing or breathability for the price point of the garment.

This 'membrane' that we are banging on about is applied directly to the inside of the garment and can look like a clear or milky plastic bag when opening up the garment. The process works as water drops are too big to penetrate the membrane and therefore keeps the fabric waterproof and win-resistant, however, sweat vapors are tiny and will be expelled out; sort of like a one-way door situation.

It can be a difficult task trying to pick the right jacket for the right occasion, but hopefully the team here at Snowcentral are able to make your shopping experience a smooth one by helping you understand what it is you want or need in snow outerwear. Breathability, insulation and waterproof ratings are all words you will hear while choosing your kit in preparation for the best winter yet. So, what does it all mean?

What Do Waterproof Rating Numbers Mean?

In the ski and board world, we use two different numbers to rate the waterproofing and breathability of fabrics that are used to make the outerwear. In both cases, the lower the number the lesser the rating. So, the higher the waterproof rating, the more water the garment can withstand, but this also means the price will increase.

To measure how breathable a fabric is, we test to see how many grams (g) of water vapour is able to pass through a square meter of the fabric, from the inside to the outside in 24 hours. The other number is used to measure how waterproof a fabric is. For this we use millimetres (mm). For example, in the case that a jacket was rated at 20K, if you were to put a tube with dimensions of “1x1” over the jacket and filled the tube with water up to the 20,000mm mark before you would start to see water penetrate through the jacket.

These numbers are generally displayed with the millimetres first and the grams second, for example if it says 10,000/20,000 it has 10K waterproof rating and 20K breathability rating. 45,000mm is known to be the highest rating available on the market at the moment, any higher than that could compromise the breathability of the garment and may end up wearing like a plastic bag; which is never fun. See our guide on Choosing A Snow Jacket for more information.

[table id=8 /]

You may be sitting there and wondering why all of the gear we use in the snow isn’t simply 100% waterproof. The truth is that if it were completely waterproof, we would be sweating bullets while out on the slopes and soon be completely drenched from our own sweat. Manufacturers design outerwear to different standards of water resistance and the testing is not standardized. That’s where the breathability rating comes into play.

Humans are active, we perspire and sweat. We create a moist atmosphere inside every garment that we wear and as activity increases moisture from perspiration builds up inside the garment. The moisture created inside our clothes can make us uncomfortable as well as increasing the potential to overheat whilst active. Then when we are slowing down and standing still, it can cause you to become very cold.

What's a Breathability Rating?

Breathability refers to ‘moisture wicking’. It is the extent to which body vapor and perspiration passes through a fabric and the membrane inside the garment.

For example, a 10K breathability rating means that during a typical 24hr period, in normal active conditions, 10,000gm of perspiration or vapor will be transferred through the fabric. If you think of it as a plastic poncho in the rain; that feeling of being sweaty underneath that plastic poncho in the rain is dramatically minimised when wearing a garment that has a breathability rating.

So why is breathability so important? Most fabrics used in snowboard and ski techwear are very water resistant. Depending on how and where you ride, any outwear with a rating of 10K waterproof rating or higher will be able to keep you reasonably dry in a storm, although the breathability could vary quite dramatically.

Realistically, if you are the kind of rider who likes to stay on the piste, using the lifts and never hiking or climbing, a high breathability rating tends not to matter much. Generally, that kind of rider won’t work up too much of a sweat and therefore perhaps the money is better spent on a few extra days on the hill. Alternatively, if you’re a serious rider and are constantly hiking up to find new untouched lines, so you may be skinning for hours on a serious backcountry excursion; you will want some outerwear that keeps you warm and dry, while also remaining lightweight. This allows the water vapour to escape the jacket but not the heat.

There are some factors that can influence the breathability of the jacket and pants, the main one being how clean the jacket is. If your jacket is dirty or contaminated with dirt, grime, oils, etc. from sunscreen, moisturizer or natural oils, this can block the pores of the jacket and nothing will be able to escape, negatively affecting the jacket’s breathability.

Insulation Rating

Snowboard and ski outerwear come in two models: insulated and not insulated. Insulation can be synthetic or natural. The synthetic is usually made from spun polyester, whereas the natural one, of course, uses natural fibres such as goose or duck down. An insulated winter jacket is generally insulated using a body map, simply using a heavier, warmer layer of insulation around your core with a lighter version of the same thing used in the hood and arms of the jacket. They measure insulation in grams per square meter of the fabric. The higher the number, the warmer and thicker insulation it will have. Typically, you will see it displayed on the garment as, for example: “80 grams body / 60 grams arms and hood”.

The Outer Layer

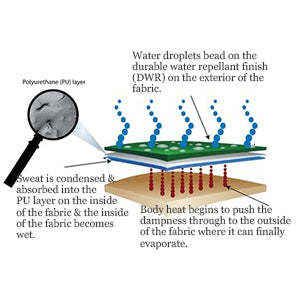

Over time outerwear manufacturers have developed, and are still developing, new and unique ways to allow water vapour to escape from the inside while protecting us from the outside. They do this using layers. The outer layer is called ‘face fabric’, this fabric is mostly for show and for protection; it is treated with a solution called Durable Water Repellent. This prevents the face fabric from soaking up water. This outer layer is often nylon or polyester teamed with a laminated coating made up of Polyurethane.

Membrane

The most important part of the fabric is its membrane. The membrane has the job of keeping water out, it does this by having tiny holes that allow for water vapour to escape, but at the same time not large enough to allow water droplets inside.

Fabrics with ePTFE laminated membranes like GORE-TEX are the leaders in waterproof and breathable fabrics. They offer the best formula to provide the wearer with waterproofness and breathability. As technology is increasing, it is allowing thinner and thinner layers to be made, as well as high-performance polyurethane and polyester membranes which are starting to take up a greater share of the market. Membranes come in many different prices and forms, so it is important that you choose the right garment for your needs.

Snow outerwear can also come with a coated, non-laminated membrane; the difference between these two is that one is painted on and the other, laminated. The coated fabrics have great water resistance but in comparison, are not as breathable as the laminated membrane. These types of fabrics are generally less expensive and are great for emergency weather protection or activities that don’t require a lot of physical exertion.

Durable Water Repellency (DWR)

DWR, or Durable Water Repellent, is a coating on the outside of the fabric (either fluoropolymers, silicones or hydrocarbons) that forces the water to bead up and off fabrics and prevents saturation. This coating increases the contact angle or surface tension of the fabric when water comes into contact with it. However, it is not a waterproofing treatment by itself and does not provide protection in extended wet weather. Therefore, you will need to look out for waterproof ratings in conjunction with DWR coatings when considering what jacket is right for you.

All jackets are treated with DWR and depending on how much a person uses the garment, it will need to be re-applied at different times to ensure the garment is performing at its best. Once the DWR has worn away, the garment will be less breathable and there is also a chance that the face fabric will absorb water. This is referred to as “wet out”, when this happens it severely affects the fabrics ability to wick away moisture from the jacket. Even though the garment will remain waterproof, the capacity to remove your sweat will be lessened significantly.

It is very common for people to think that the jacket is no longer waterproof or is leaking. What is actually happening is that, because the water vapour hasn’t had the chance to escape, it is condensing and turning back into liquid when it hits a wet face fabric. There are certain products that you are able to purchase to re-proof the DWR coating.

Tech Wear

There are three forms of tech wear you are able to purchase: 2 layer (2L), 2.5 layer (2.5L) and 3 layer (3L). These layers are referring to the construction of the garment.

2 layer (2L)

2L construction is the most commonly used, as these use very similar face fabrics and membranes as the 3L. The 3L has a bonded third layer on the inside and the 2L has a fabric or mesh lining that hangs loosely within the jacket. A 2L jacket will be the cheapest on the market. They are considerably bulkier then the 2.5L and 3L jackets. Although they can potentially offer the same level of weather protection.

2.5 layer (2.5L)

2.5 layer fabrics do not have a separate sewn in lining or a bonded mesh lining. Instead they include a very fine raised pattern that is screened onto the membrane so that the membrane is kept away from the skin. Keeping the fabric off the skin helps protect the laminate from your body oils, sunscreen and anything else that is able to break down the material over time. 2.5L outerwear is lightweight and packable. Gore-Tex is the best example of a 2.5 Layer.

3 layer (3L)

The most durable, packable, breathable and of course, the most expensive construction is the 3 Layer. The 3L consists of an outer layer or face fabric, which generally is made up of nylon of polyester bonded with a membrane. Finally, an extremely lightweight backing fabric is attached to the interior which helps protect the waterproof laminate from being dissolved by oils on the skin.

What Is Seam Sealing?

Ever heard of seam sealing, seam taping or seam welding? Seam sealing, or seam taping as it is referred to sometimes, is a process in which the manufacturer covers the tiny holes made by the needle in the sewing process. Seam welding is the alternative, it attaches separate pieces of fabric by either fusing the material together using the heat generated by ultrasound, or using a heat adhesive film. Welded items have the advantage of being much less bulky and lighter, as well as creating no holes for water to escape. Sewn seams must be sealed with seam tape to ensure that no water penetrates the garment, although has the advantage in strength. It is very common to hear about a jacket being “critically taped” or “fully taped”. When a jacket is only “critically taped” it means that only the exposed seams are sealed; usually the front sipper, neck and shoulders for jackets, and the side and center seams for pants.

There are some manufacturers that do a better job of sewing than others. The general industry standard is 8-10 stitches per inch. More stitches per inch in the construction is slow and uses more thread, therefore the garment is stronger and lasts longer. The thread that is used in the construction isn’t any old thread that you would find in your mums sewing box, it will generally be a 100% polyester thread in a heavy #40 weight.

Fully Seam Sealed

Fully Seam Sealed refers to the manufacturing process of the garment. Each seam has a thin film of tape applied to the interior of the seam where minute holes are left from the sewing process. By having a fully seam sealed garment, the waterproofing will keep its integrity and ensure moisture is kept away from the body.

Critically or Strategically Seam Sealed

This is exactly the same process as Fully Seam Sealed garments, however only the seams that are coping the brunt of the external elements is considered. Areas such as the shoulder, neckline, and sometimes the hood and biceps in a jacket and the crotch, buttock, and sometimes hips in pants are critically or strategically seam sealed.

Outerwear Fabrics and Insulation

Polyester

All outerwear, and clothes for that matter, are made up of lots of different types of fabrics. All of these fabrics possess different factors which manufacturers use to determine where and why they use them. Polyester is the base fabric to all kinds of apparel because it is stretchy, quick drying, mildew resistant, strong and resistant to shrinking. All of these properties make it a perfect material to be used in winter apparel. When polyester threads are tightly woven together, they actually become water resistant and durable, however, these materials still need to be DWR coated or laminated to heighten these characteristics.

Nylon

Another very typical material used in outerwear manufacturing is nylon. Nylon is an exceptionally strong material with low absorbency and highly elastic characteristics. Nylon is able to be dyed easily, simple to wash and is very resilient. Again, like polyester, this fabric is coated to increase its capabilities.

GORE-TEX

GORE-TEX, is something that, if you have ever been into an outdoor store, you would have heard of before. Gore-Tex has a wide range of uses, from clothing to medical equipment. Gore-Tex has approximately 9 billion holes per square inch. These tiny holes are microscopic and the openings are 20,000 times smaller than a drop of water. This technology is the foundation for a material that is breathable yet still waterproof. In outerwear, Gore-Tex membranes are typically attached to a nylon or polyester base fabric to create a protective shield against rain, snow, wind and the cold. The original makers of Gore-Tex insist that any manufacturer using its technology must completely seam seal the entire garment so that no moisture can penetrate the minuscule holes made by stitching during assembly, so that it is ensured that the final product will be leak proof and sound.

Active Core Technology

Active Core Technology, from the manufacturers at Ride, is an example of a different technology that is used for insulation in snow outerwear. They use their own kind of rating system, ranging from 1-4. The first being the lowest insulation that is ideal for layering. The second including well-placed areas with light insulation to manage body heat, whereas the third has very similar features which only increase the weight of the insulation. The top of the tier is number 4 which is fully insulated and is built to withstand the coldest of days.

Sympatex

Sympatex from the makers of Pure Snow, have developed a special membrane that absorbs the water vapour and removes it through the clothing to the outside. The difference to other membranes is that the higher the physical activity, the better Sympatex works. Sympatex, unlike other technologies, is durably waterproof, whether the jacket is washed, dry cleaned or soiled by fuel or oils; as well as being 100% wind proof. Sympatex is also 100% recyclable and at Pure Snow they have developed a procedure to help reduce the material input dramatically.

Primaloft

Primaloft is yet another example of a technology that Dakine uses is many of their outerwear items. Primaloft uses a synthetic down, which is made up of microfibers and macrofibers that possess many of the same features as down. It has proven to be equally as warm as down, but Primaloft has improved wetting and drying characteristics, as well as great loft retention when the material is wet. It has many outstanding factors; it is as warm as down and lightweight, as well as durable.

3M Thinsulate

3M Thinsulate is a type of insulation that works by trapping air molecules between your body and the outside. The more air that becomes trapped within the material, the better the insulation performs. The microfibers that are found in Thinsulate insulation are far smaller than other fibres, and they trap more air in less space. Thinsulate is extremely breathable and machine washable as well as dry cleanable. This Roxy Jet Ski Jacket has Thinsulate insulation.

Buying snow gear in the olden days was, of course, a lot easier, with less choice and nowhere near as much technology things have definitely changed a bit regarding outerwear. Around the time snow sports became popular, women even used to wear “snow skirts”; these were generally for a more advanced skier of course. Although in this day and age, realistically – there are really no bad fabrics.

If you are going to purchase your outerwear from a top of the range outdoor shop, regardless of what you are going to purchase, you will most likely be getting a garment that will keep you dry. However, there is a huge difference in durability, breathability and long term waterproofness, as spoken about above. These are the elements of the garment that are going to inevitably affect your time on the slope.

It is essential that you choose a jacket and pants that are designed well and suits your personal needs. A poorly designed and ill-fitting jacket will never perform the way the buyer wants or be comfortable, regardless of the fabric qualities. You always get what you pay for with these things and if you take proper care of your jacket you will end up getting many, many years of fantastic use from it.

When purchasing a jacket, these are all very important areas to keep in mind. Anything over 10,000 for waterproofing and breathability is suitable for conditions all over the world; Australia to Canada, Canada to Japan. If you need any further assistance with any of these concepts, give our friendly staff a call any time!